Understanding the 5-Axis Machining Center

Contents

- 1. What Is a 5-Axis Machining Center?

- 2. Structure of a 5-Axis Machining Center

- 3. Types of 5-Axis Machining Centers

- 4. How Does Five-Axis Machining Work?

- 5. Why Choose 5-Axis CNC Over Traditional Machines?

- 5.1 High Precision at Every Step

- 5.2 Easier Machining of Complex Parts

- 5.3 Less Setup Time, Less Downtime

- 5.4 Better Efficiency and Consistent Quality

- 6. Industries That Benefit from 5-Axis Machining

- 7. How to Keep Your 5-Axis Machine Running Smoothly

- 8. The Future of 5-Axis Machining

- 9. Conclusion

From the sleek frame of your laptop to the flowing curves of a car body and even the elegant joints in modern furniture, CNC machining plays a hidden but vital role in everyday products. And when it comes to handling not just straight lines but also complex, curving surfaces with precision and speed, 5-axis CNC machining centers are leading the way.

Unlike older machines that could only move in three directions, 5-axis technology allows the cutting tool to tilt and rotate, making it possible to create both sharply geometric shapes and smooth, organic streamlines in a single setup.

In this guide, we’ll explore what makes 5-axis machining so powerful, how it works, and how it’s shaping the future of modern manufacturing.

What Is a 5-Axis Machining Center?

In simple terms, a 5-axis machining center is a CNC machine that can move a cutting tool in five different directions to create complex parts with exceptional precision.

CNC, or Computer Numerical Control, refers to machines that follow programmed instructions to automatically cut, drill, and shape materials into exact designs. Traditional CNC machines move in three basic directions: side-to-side (X-axis), front-to-back (Y-axis), and up-and-down (Z-axis).

5-axis machines take it further by adding two rotary movements. This extra flexibility allows them to machine complicated surfaces, curves, and angled features in a single setup—saving time, boosting accuracy, and enabling designs that would be difficult or even impossible on older machines.

Structure of a 5-Axis Machining Center

In 5-axis CNC milling, the machine is capable of moving a tool or a workpiece along five different axes—three linear and two rotary. Depending on how these movements are configured, 5-axis machines generally fall into two categories:

Table-Table design:

The rotary axes (typically A and C) are built into the machine’s table. The tool remains stationary while the workpiece tilts and rotates. This design is ideal for high-precision work on small parts, such as molds and medical components. It offers excellent stability and repeatability, making it ideal for tasks that demand fine tolerances. However, it’s less suitable for large or heavy parts, as the rotation can introduce excessive load and compromise accuracy.

Head-Head design:

The rotary axes are integrated into the machine’s cutting head. In this case, the workpiece stays fixed, and the cutting tool moves and tilts. This configuration is particularly advantageous for large, heavy, or irregularly shaped parts that are difficult to reposition. It provides a wide range of motion and supports complex angular cuts, especially when used with RTCP (Rotational Tool Center Point) for advanced surface machining. While the Head-Head type offers greater flexibility and is capable of handling larger parts, it typically comes with a more complex structure and higher cost.

Types of 5-Axis Machining Centers

5-axis machining centers come in several types, depending on where the rotary movements happen—at the head, the table, or both. Here are the three main types:

Head-Head Type

Both rotary movements are built into the cutting head itself. This setup offers excellent flexibility and is ideal for machining large, heavy parts with lots of complex angles.

Table-Table Type

In this design, the rotary movements happen on the worktable, often using a cradle-style system. It’s a great choice for smaller, highly detailed parts where maximum precision is needed.

Head-Table Type

One rotary axis is placed in the cutting head and the other on the table, combining flexibility and stability. This hybrid design offers a good balance for handling a wide range of parts.

How Does Five-Axis Machining Work?

The process of 5-axis machining includes four key steps:

Step 1: CAM Programming

The process begins with CAM software (Computer-Aided Manufacturing), which allows engineers to design a 3D model of the part and automatically generate the machine instructions needed to create it. This eliminates the need for manually writing complex code and speeds up preparation.

Step 2: Machine Setup

Tool Calibration: Setting up the cutting tool to accurately understand its position relative to the workpiece.

Workpiece Setup: Clamping the material securely to ensure it stays perfectly in place during cutting.

Step 3: Machining

The machine follows the CAM-generated instructions to cut and shape the part. Modern 5-axis machines may use advanced features like live monitoring and RTCP (Rotating Tool Center Point) to enhance precision and maintain tool accuracy throughout complex movements.

Step 4: Finishing

Once cutting is complete, the part may undergo inspection, cleaning, and surface treatments depending on the intended use.

Why Choose 5-Axis CNC Over Traditional Machines?

1. High Precision at Every Step

With better programming, automatic calibration, and RTCP (Rotating Tool Center Point) guiding every move, 5-axis machines keep mistakes to a minimum and precision to a maximum—especially important when cutting expensive materials or tight-tolerance parts. RTCP is a key feature in advanced 5-axis machining that ensures the tip of the tool stays perfectly aligned with the programmed path, even when the head tilts or rotates. Without RTCP, tool pivoting would cause the cutting point to shift, leading to dimensional errors or surface defects. With it, the machine dynamically compensates for any angular movement, enabling smoother motion and accurate cutting—especially valuable when working with curved or angled surfaces.

2. Easier Machining of Complex Parts

Making parts with angled surfaces, deep curves, or complicated features? 5-axis machining makes it possible in one setup. In older systems, these parts would have needed multiple setups, special jigs, angled clamps, or even manual sanding afterward to smooth out imperfections. 5-axis machines can follow the curves naturally, giving you a smoother, cleaner finish right off the machine.

3. Less Setup Time, Less Downtime

Conventional machining often means stopping, flipping, reclamping, and double-checking alignments again and again. Each setup takes time and risks errors. 5-axis machining slashes all that because it can reach different sides and angles in a single operation.

4. Better Efficiency and Consistent Quality

Fewer setups also mean fewer chances for mistakes. Plus, the smoother cutting motions of a 5-axis machine produce better surfaces and more consistent dimensions—crucial in industries like aerospace, automotive, and medical equipment.

Industries That Benefit from 5-Axis Machining

Aerospace

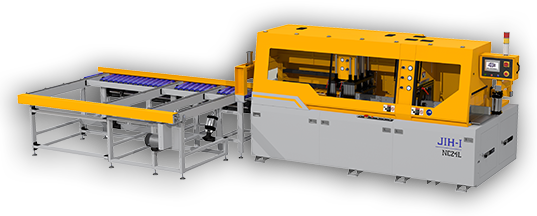

From turbine blades to structural frames, aircraft parts often have complex curves and tight tolerance needs. (Machines like the JIH-CNC SD5 Traveling Double-Column 5-Axis Machining Center are built to handle these big, intricate jobs.)

Automotive

Engine parts, transmission systems, and lightweight aluminum structures all benefit from faster, more precise machining.

Medical Equipment

Implants and surgical tools require tiny details and perfect finishes—things that 5-axis technology makes much easier.

Precision Machinery and Mold Making

Making tools, dies, and molds often means deep cavities and tight corners. 5-axis machines cut them faster and more accurately, saving time and polishing effort.

How to Keep Your 5-Axis Machine Running Smoothly

Spindle Maintenance

Keep it lubricated and listen for strange noises or vibrations. Early repairs save major headaches.

Tool Holder and Clamping System Care

Always clean these before swapping tools to avoid accuracy problems caused by trapped chips.

Air and Cooling System Checks

Make sure there are no leaks and that coolant levels and temperatures are right. Proper cooling keeps cutting performance sharp.

Rotary Axes and Drives

Regularly check that the A, B, or C axes move smoothly and hold their positions accurately. Worn components can cause subtle but costly errors.

Control System and Sensor Calibration

Smart sensors must be calibrated and monitored regularly to detect wear and prevent unplanned downtime.

The Future of 5-Axis Machining

Looking ahead, 5-axis machining will continue to evolve with smarter automation. Robotic arms are expected to handle loading and unloading tasks, increasing machine uptime and freeing up workers for more creative work like design and process optimization.

Conclusion

5-axis CNC machining isn’t just another manufacturing upgrade—it’s a complete shift toward smarter, faster, and more precise production. Whether you're making aerospace parts, medical devices, automotive components, or precision molds, 5-axis technology gives you the flexibility and accuracy to stay ahead in an increasingly competitive market.

If you’re ready to explore how 5-axis machining can transform your production, contact JIH-I Machinery today and discover solutions built for the future.