Understanding Friction Welding Machines: Everything You Need to Know

Contents

- 1. What is Friction Welding?

- 2. What is a Friction Welding Machine?

- 3. Friction Welding Machine Operation Procedure

- 4. Applications of Friction Welding Machines

- 5. Advantages of Friction Welding Machines

- 6. Sustainable Benefits of Friction Welding

- 7. Future Trends

- 8. Best Choice to Upgrade Processing Quality

In manufacturing, joining different materials or components is essential to create products that are both durable and functional. Welding is one of the most common methods used to connect materials, and friction welding is a particularly effective technique for creating strong and reliable joints.

What is Friction Welding?

Friction welding is a solid-state joining method that generates heat by rubbing two workpieces together. The heat softens the material at the joint, allowing it to fuse under pressure, while impurities are pushed out, ensuring a strong bond.

The process doesn’t require filler materials, reduces heat damage, and is especially effective for metal forms like rods, tubes, and dissimilar materials. Fully machine-controlled, it is repeatable and monitored to ensure high quality.

What is a Friction Welding Machine?

A friction welding machine is a specialized device that uses rotational or linear motion to create heat through friction between two workpieces. This heat softens the materials and allows them to join under pressure.

The machine features advanced control systems, sensors, and monitoring tools to precisely adjust welding parameters and track the process, ensuring optimal results.

It is an ideal machine for high-volume production because it is efficient, highly repeatable, and requires minimal manual intervention.

Structure and Components

1. Base & Frame

The base and frame support all mechanical components, ensuring the machine's stability and rigidity. These parts are made of high-strength steel or cast iron to withstand the immense pressure and vibration during the welding process.

2. Spindle & Drive System

The main spindle and drive system is crucial for creating the motion and pressure needed to join parts. It controls the rotation or movement of the workpieces and applies pressure during the welding process.

- Rotary Friction Welding (RFW): It controls the rotation of one workpiece while the other stays fixed.

- Linear Friction Welding (LFW): It controls the back-and-forth motion of one part while the other remains stationary.

- Friction Stir Welding (FSW): It controls the rotation of a tool that stirs and joins the workpieces. Especially suitable for welding soft metal sheets such as aluminum alloys and copper alloys.

3. Clamps and Workpiece Fixturing System

This system ensures the workpiece is securely positioned, preventing displacement during welding. High-precision hydraulic or mechanical clamping mechanisms ensure perfect alignment, improving welding accuracy.

4. Control & Monitoring System

The control and monitoring system, managed by a PLC (Programmable Logic Controller) or CNC (Computer Numerical Control) system, adjusts welding parameters such as rotation speed, pressure, and feed rate. It is equipped with sensors to measure force, temperature, and displacement, ensuring consistent and high-quality welds.

Friction Welding Machine Operation Procedure

1. Workpiece Preparation

The surfaces of both workpieces must be precisely machined to ensure they are flat and free of impurities. Proper fixtures and welding parameters must also be selected to ensure a strong and reliable joint.

2. Preheating and Friction Heating

Preheating and friction heating generate the necessary heat at the contact interface between the materials. This heat is produced through friction, softening the materials and preparing them for joining.

- Rotary and Linear Friction Welding: One workpiece moves—either by rotation (RFW) or linear motion (LFW)—while the other remains stationary. The friction between the surfaces generates heat, softening the materials for welding.

- Friction Stir Welding: Both ends of the materials stay stationary, while a rotating tool generates frictional heat, stirring the material at the joint interface and softening it for the weld.

3. Welding Forming and Cooling

After heating, pressure is applied to form a solid joint, ensuring strength and minimal gaps. Cooling is then carefully controlled to prevent distortion and maintain the strength and stability of the weld. Proper cooling is crucial for preserving weld quality and ensuring the joint's long-term reliability.

Applications of Friction Welding Machines

Friction welding is used across industries like automotive, aerospace, energy, military, and construction to create high-strength, reliable joints in critical components, such as vehicle chassis, aircraft parts, and pipeline connections.

- The Automotive Industry uses friction welding to create lighter and stronger vehicle components, such as cooling systems, chassis, and electric vehicle battery components.

- The Aerospace Industry applies friction welding to produce ultra-light, high-rigidity structures, replacing traditional rivets. It was first adopted by NASA to weld the Space Shuttle’s external fuel tanks. Applications include airframe structures, wing assemblies, cabin seats, cabin flooring, and fuel tanks.

- The Military & Shipbuilding Industry benefits from friction welding to ensure robust joints in extreme conditions, such as in torpedo hulls and submarines.

- The Energy Industry uses friction welding to form crack-free joints in nuclear power plants and oil pipelines, extending their lifespan. It also strengthens components like wind turbine main shafts, making them suitable for high-load operating environments.

- The Construction Industry relies on friction welding to join aluminum alloy profiles, creating durable, reusable building templates that reduce construction waste and support eco-friendly trends.

Advantages of Friction Welding Machines

Compared to traditional welding methods, friction welding offers several key advantages that make it a smarter, cleaner, and more reliable choice for modern manufacturing.

Environmental & Safety Benefits:

The process produces no arc, smoke, or toxic gases, and doesn’t require filler or shielding gases, making it safer and more eco-friendly.

High Strength & Quality:

Friction welding produces joints stronger than the base materials, avoiding common defects like cracks and pores.

Low Heat Input & Minimal Deformation:

The solid-state process minimizes heat-affected zones, preserving material properties and reducing residual stress.

High Efficiency:

With rapid heating and short cycle times, friction welding boosts production speed, ideal for high-volume manufacturing.

Strong Material Compatibility:

It can join a wide range of metals, including dissimilar materials like aluminum and copper.

No Filler Materials Needed:

Friction welding doesn’t require fillers or shielding gases, reducing material costs and environmental impact.

Easy Automation:

These machines are easy to integrate into automated production lines, enhancing efficiency and repeatability.

Sustainable Benefits of Friction Welding

Friction welding aligns with sustainable manufacturing by improving efficiency and reducing environmental impact, energy consumption, and carbon emissions. It supports several Sustainable Development Goals (SDGs):

Goal 7: Affordable and Clean Energy:

The process uses less energy than traditional methods, contributing to cleaner production.

Goal 9: Industry, Innovation, and Infrastructure:

It advances innovation in manufacturing, improving efficiency and reducing environmental impact.

Goal 12: Responsible Consumption and Production:

By eliminating consumables like filler metals and shielding gases, friction welding reduces waste and production costs.

Future Trends

Friction welding is evolving with higher automation, broader material compatibility, and lower energy consumption.

Low-Force Friction Welding:

A new technique that reduces the force required by using induction heating, improving joint strength and shortening welding times.

Robotic Friction Stir Welding (RFSW):

In the era of Industry 4.0, robotic systems like KUKA robots are used to weld EV battery casings, reducing costs compared to traditional welding.

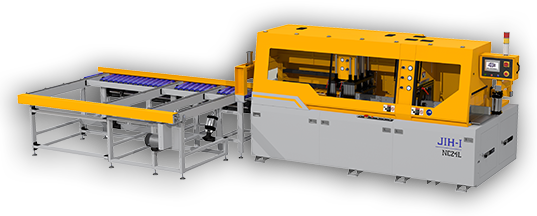

Best Choice to Upgrade Processing Quality

Friction welding technology provides a transformative solution for industries seeking strong, sustainable, and efficient joining methods. Choosing the right Friction Welding Machine from JIH-I ensures not only top-quality equipment but also a trusted and experienced partnership. Contact JIH-I right now if you need more information about our products and service.