How to Automate Your Factory: Step-by-Step CSV Transfer and Cutting Workflow

In modern industrial automation, precise data transmission and automated control are crucial. JIH-I Machinery offers an optional CSV (Comma-Separated Values) feature that enables users to input and transmit cutting parameters quickly and accurately, improving production efficiency and reducing human error. This technology plays a key role in smart manufacturing, enabling cutting operations to become more automated and precise.

When the CSV function is enabled, the machine will automatically generate an editable CSV file formatted to match the machine’s operational requirements.

(Note: While CSV is an open standard, the required format may vary depending on the machine and production environment. The actual integration process can be customized according to the customer's needs.)

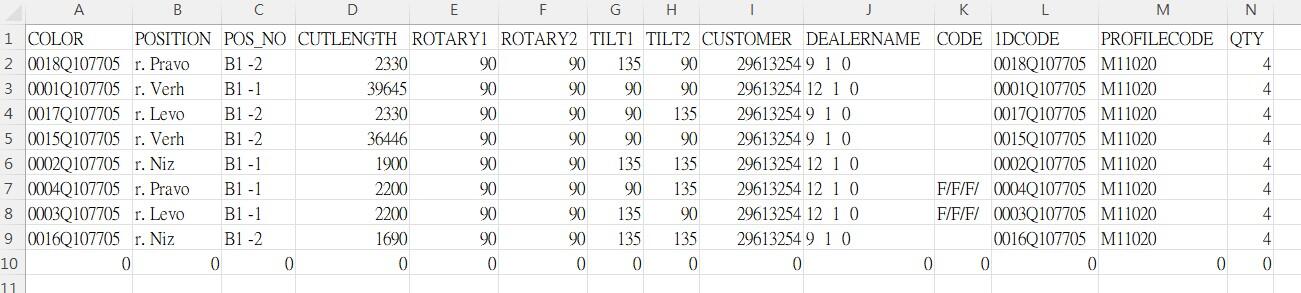

1. Machine Generates a CSV File

✅ The file includes key settings such as cutting length, angle, and tilt angle.

✅ The CSV file can be opened and edited on a computer, ensuring flexibility in operation.

2. User Inputs Cutting Requirements

✅ Cutting dimensions and angles can be entered according to production needs.

✅ The file can be modified manually or exported from a documentation system used by the customer (such as an ERP system or other third-party applications), provided the system supports compatible CSV export functions.

⚠️ In practice, whether an ERP or other management system can generate a correctly formatted CSV file depends on the specific system design.

For example, in Europe, Orgadata and LOGICAL are commonly used, while in the U.S., PypeServer is currently under evaluation. Each system may require customized formatting and transmission logic according to the customer's requirements.

JIH-I Machinery can assist in programming interfaces and format conversions based on the end user's system specifications.

3. Transferring the File to the Machine

📌 FTP Method: The computer and the machine’s HMI log into the same IP address, allowing direct FTP transmission. Suitable for networked environments.

📌 USB Method: The edited CSV file is saved onto a USB device and then inserted into the machine. Ideal for standalone environments.

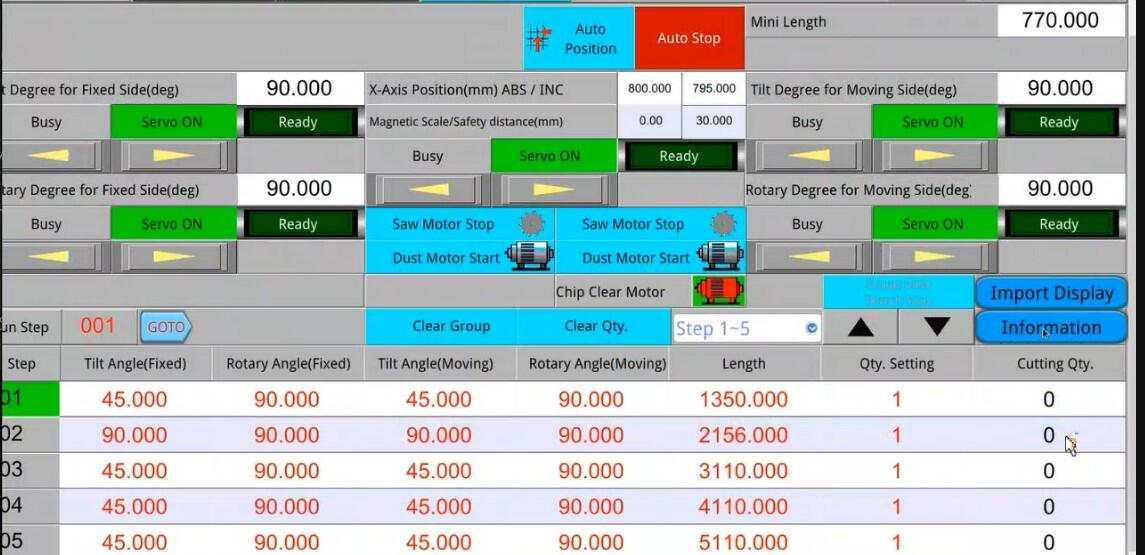

4. Machine Reads the CSV File

✅ The machine’s HMI interface displays all the cutting information from the CSV file.

✅ Users can review and confirm the data before initiating machine operation.

5. Start Cutting

✅ Press the start button, and the machine will automatically execute cutting operations based on the CSV settings.

✅ This reduces manual setup time and ensures a highly efficient and stable production process.

To further enhance production management efficiency, a barcode printer can be added to automatically convert cutting data into QR codes, supporting traceability and quality management.

✅ Automatic QR Code Generation:

Each completed product’s information (length, angle, project ID, etc.) is automatically encoded into a QR code.

✅ Fast Product Information Lookup:

By scanning the QR code, users can instantly access complete production information, improving tracking efficiency.

✅ Supports Production History and Smart Warehousing:

Through barcode and data records, each batch remains traceable and transparent, optimizing the supply chain.

⭐ Standardized Data Transmission: Ensures consistent data exchange between systems and reduces manual input errors.

⭐ Increased Production Efficiency: Allows batch input of complete cutting parameters, reducing setup time.

⭐ Supports Multiple Transfer Methods: Compatible with both FTP and USB for flexible integration.

⭐ Enhanced Traceability: With barcode integration, users can quickly identify the source and specs of each product.

⭐ Part of Smart Manufacturing: Can be integrated with platforms such as ERP (e.g., SAP, NetSuite), MES, and BIM scheduling systems to enhance automation in production lines.

By implementing the CSV function, JIH-I Machinery's equipment can be seamlessly integrated into a smart manufacturing environment, improving cutting precision and production management efficiency—bringing your operation closer to Industry 4.0.